Injection Molding

Injection molding - seen holistically

High-tech injection molding and sustainability are not mutually exclusive. True to the company motto "We just get it done", we suggest building bridges between energy-consuming injection molding technology and renewable energies. We already installed a highly efficient 600 kWp photovoltaic power plant on our factory roofs years ago and thus benefit from the solar energy we harvest ourselves.

Renewable energies, combined with the use of the latest digital technologies in all areas of the company, are how we ensure long-term economic efficiency and use valuable resources sparingly.

Efficient injection molding

- DFM tools as the basis for rational quality manufacturing

- Highly qualified application technologists develop the best possible series process

- A high level of automation ensure error-free and fail-safe production

- Productivity due to CIP and in-production process optimization

- Continuous development of our employees at the technical and team level

Digital injection molding

- Service module for machine and mold maintenance

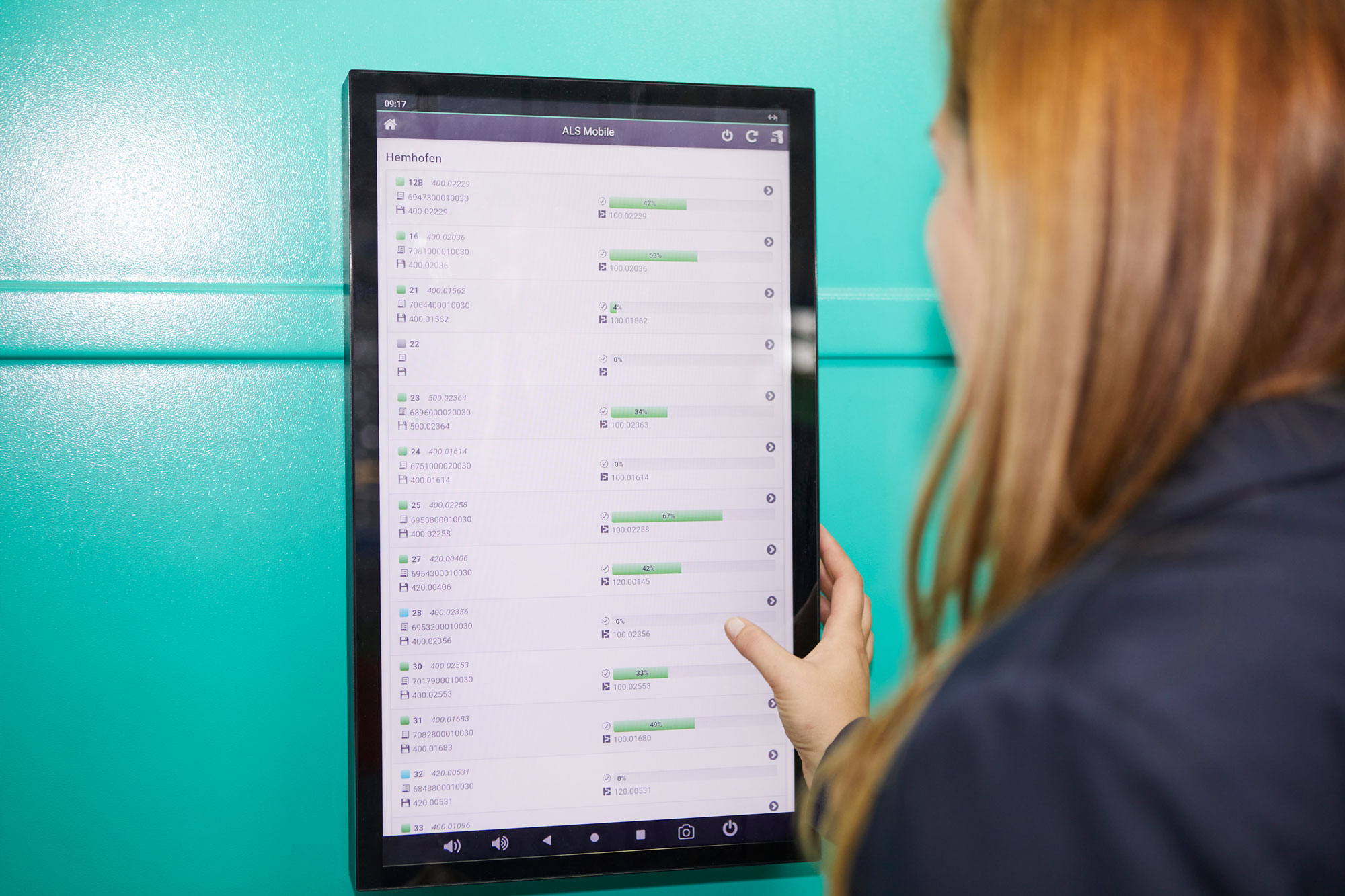

- Fully networked machine park using the ARBURG host computer system (ALS)

- Intelligent production planning networked with the customer and suppliers

- Document management with versioning in ELO (an electronic filing system)

Sustainable injection molding

- Resource-saving component development DF(R)M – design for (resource-saving) manufacturing

- Avoidance of sprue with comprehensive use of hot runner systems

- Regeneration of plastic waste to produce secondary raw materials

- Recovery of process heat for heating and hot water (elimination of the gas heating since 2019)

- 600 kWp photovoltaic power plant for internal consumption

- Returnable packaging systems as a non-disposable solution for transport

You will find an overview of our current machine park here - download PDF