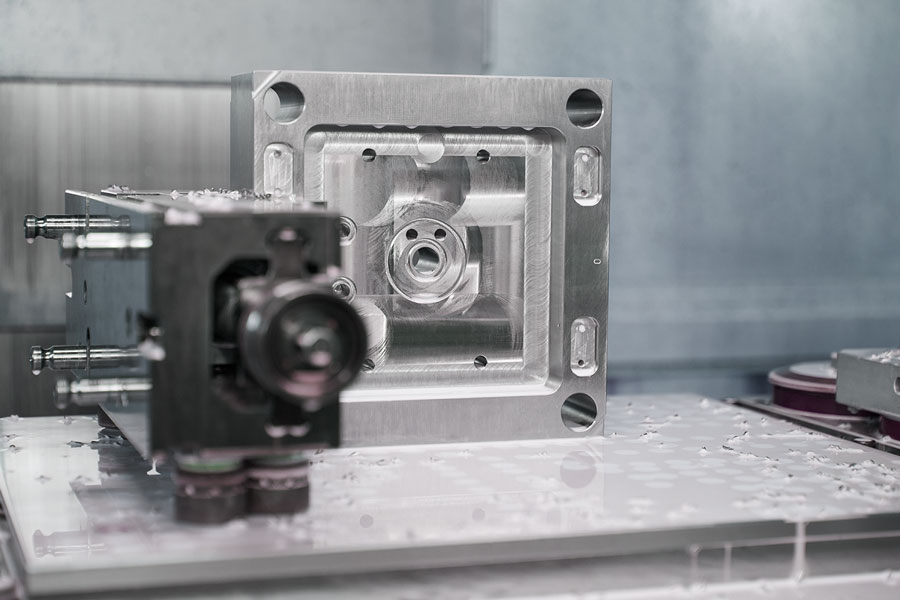

Moldmaking

Injection molding is our passion - moldmaking too, of course!

In line with our motto: "We just get it done... ourselves", we always have had highly efficient inhouse moldmaking, which minimizes long repair and development times at external service providers. In our inhouse moldmaking with its departments for maintenance and new mold creation, we ensure fast availability, flexibility, and fast throughput times for our customers.

New mold creation

- Franconian master molds with high precision and long life

- CAM system: Autodesk Power Mill

- Efficient workpiece machining due to automatic pallet change systems

- Electrode production in copper and graphite

- Multiple-component molds, insert and outsert molds for prototype and series production

- Production of fixtures for module assembly including complex automation solutions

Maintenance

- Host-computer-assisted (ALS), preventive mold servicing

- Fast spare part availability due to inhouse production

- Short repair throughput times

- High mold availability

- CIP-oriented repair measures due to interdisciplinary know-how transfer

You will find an overview of our current machine park here - download PDF